Vapor Pressure Testing: A Comprehensive Guide

Vapor pressure testing is a critical process used to measure the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases at a given temperature in a closed system. This test is essential to determine the evaporation rates of liquids and identify materials with high vapor pressures at normal temperatures, which are considered volatile. Vapor pressure testing is conducted across a wide range of industries, including petrochemical, pharmaceutical, and food and beverage.

Vapor pressure is a measure of the tendency of a substance to evaporate into the air. The vapor pressure of a liquid is the pressure exerted by its vapor when the vapor and liquid are in equilibrium. The vapor pressure of a substance increases as its temperature increases. The fundamental principles of vapor pressure are essential to understand how vapor pressure testing works.

Several methods are used to measure vapor pressure, including Reid Vapor Pressure (RVP), Dynamic Vapor Sorption (DVS), and Static Headspace Gas Chromatography (SH-GC). Each method has its advantages and disadvantages, and the choice of method depends on the type of sample, the required accuracy, and the testing conditions.

Key Takeaways

- Vapor pressure testing is used to determine the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases at a given temperature in a closed system.

- The vapor pressure of a substance increases as its temperature increases.

- Several methods are used to measure vapor pressure, including Reid Vapor Pressure (RVP), Dynamic Vapor Sorption (DVS), and Static Headspace Gas Chromatography (SH-GC).

Fundamentals of Vapor Pressure

Definition and Units

Vapor pressure is the pressure exerted by the gaseous phase of a substance in equilibrium with its liquid or solid phase at a given temperature. It is a measure of the tendency of a substance to evaporate and is influenced by the intermolecular forces between the particles of the substance. Vapor pressure is commonly measured in units of pressure, such as Pascals (Pa), millimeters of mercury (mmHg), or torr.

Thermodynamic Principles

Vapor pressure is governed by the thermodynamic principles of phase equilibrium. At a given temperature, the vapor pressure of a substance in its liquid or solid phase is a measure of the extent to which the substance has evaporated into the gaseous phase. The higher the vapor pressure, the more volatile the substance. Conversely, the lower the vapor pressure, the less volatile the substance.

The Clausius-Clapeyron equation describes the relationship between vapor pressure and temperature for a given substance. It states that the natural logarithm of the vapor pressure of a substance is proportional to the inverse of its absolute temperature. This relationship is useful for predicting the vapor pressure of a substance at different temperatures, as well as for determining the enthalpy of vaporization of a substance.

In summary, vapor pressure is a fundamental property of substances that describes their tendency to evaporate into the gaseous phase. It is influenced by intermolecular forces and is governed by the thermodynamic principles of phase equilibrium. The Clausius-Clapeyron equation describes the relationship between vapor pressure and temperature for a given substance.

Vapor Pressure Testing Methods

There are various methods that can be used to measure vapor pressure. In this section, we will discuss three common vapor pressure testing methods: the Reid Method, the Knudsen Effusion Method, and the Dynamic Method.

Reid Method

The Reid Method, also known as the Reid Vapor Pressure (RVP) method, is a widely used method to measure the vapor pressure of gasoline. This method is based on ASTM D323-99a, which describes the procedure for measuring the vapor pressure of petroleum products. The Reid Method involves placing a sample of the liquid in a pressure vessel and heating it to a specific temperature. The pressure inside the vessel is then measured, and the vapor pressure is calculated using the ideal gas law.

Knudsen Effusion Method

The Knudsen Effusion Method is a technique used to measure the vapor pressure of solids and liquids. This method is based on the principle that the rate at which a substance effuses through a small hole is proportional to the square root of its molecular weight. The Knudsen Effusion Method involves placing a sample of the substance in a high-vacuum chamber and measuring the rate of effusion through a small hole. The vapor pressure is then calculated using the effusion rate and the molecular weight of the substance.

Dynamic Method

The Dynamic Method, also known as the Saturated Vapor Pressure Method, is a technique used to measure the vapor pressure of liquids. This method is based on the principle that the vapor pressure of a liquid is equal to the pressure of the vapor in equilibrium with the liquid. The Dynamic Method involves placing a sample of the liquid in a sealed container and equilibrating it with a known volume of air or inert gas. The pressure inside the container is then measured, and the vapor pressure is calculated using the ideal gas law.

In summary, vapor pressure testing is a crucial process for determining the volatility and stability of liquids and solids. The Reid Method is commonly used to measure the vapor pressure of gasoline, while the Knudsen Effusion Method is used for solids and liquids. The Dynamic Method is used for measuring the vapor pressure of liquids.

Applications of Vapor Pressure Testing

Vapor pressure testing is a crucial process in the petroleum industry, which involves measuring the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. This section explores the various applications of vapor pressure testing in the petroleum industry.

Quality Control

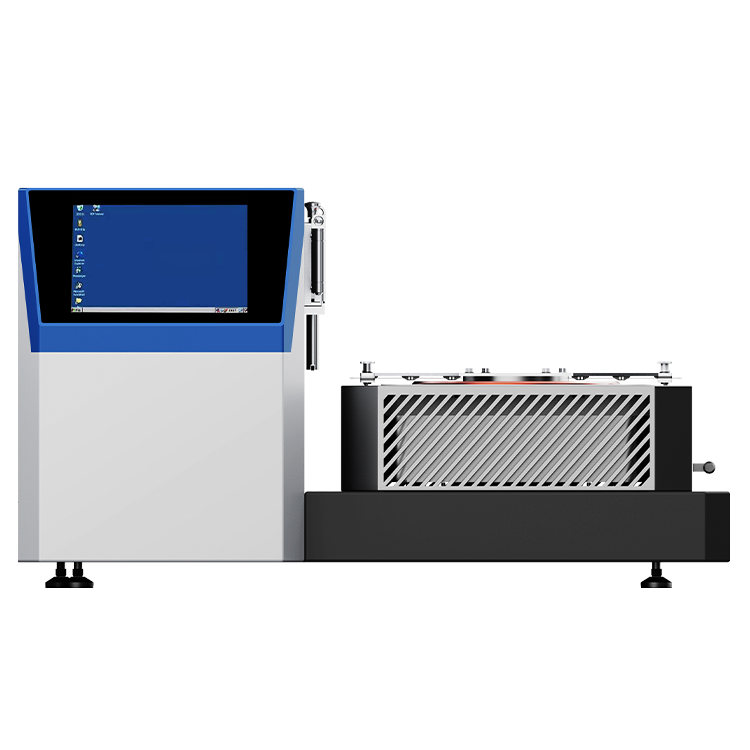

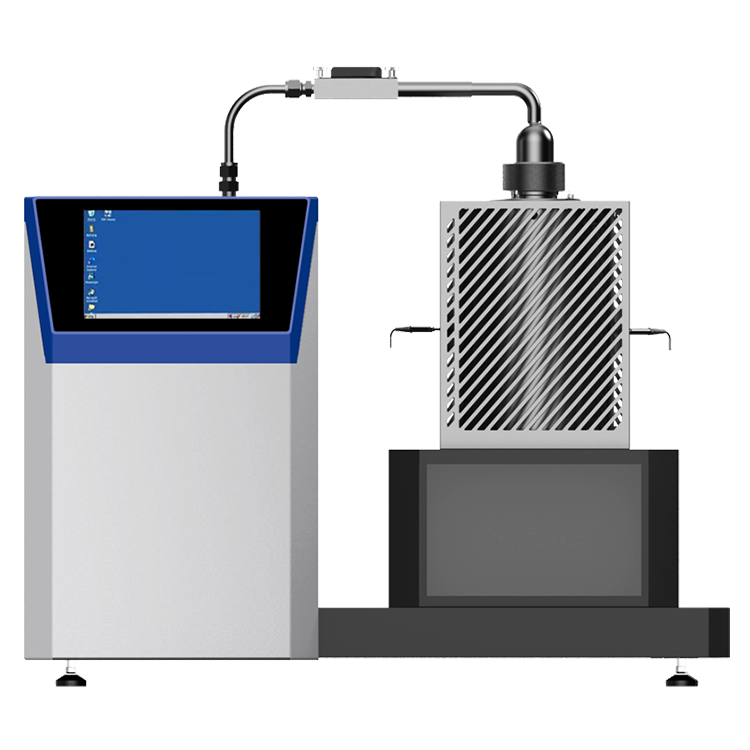

One of the primary applications of vapor pressure testing is quality control. Vapor pressure testing is used to ensure that petroleum products meet the regional vapor pressure standards. To determine the vapor pressure of a sample, there are various ASTM methods to follow. The Reid method for determining the vapor pressure of petroleum products, described in ASTM D323, is one of the most commonly used methods. Vapor pressure testing is a critical step in ensuring that gasoline, aviation fuel, crude oil, and liquefied petroleum gas (LPG) meet the required standards. ERAVAP is a compact, highly precise, and easy-to-use vapor pressure tester that is known for vapor pressure testing with unmatched precision, speed, and versatility over the widest available temperature range from -20 °C to 120 °C (4 °F to 248 °F) on the market.

Safety Regulations

Vapor pressure testing is also used to ensure safety regulations are met. Petroleum products with high vapor pressures at normal temperatures are considered to have volatile vapor, which can be hazardous. Vapor pressure testing is used to determine the evaporation rates of liquids, which is an essential factor in determining the safety of petroleum products. ASTM E1194 is a standard test method for vapor pressure, which describes procedures for measuring the vapor pressure of pure liquid or solid compounds.

Product Development

Vapor pressure testing is also used in product development. ERAVAP’s applications range from routine vapor pressure testing of gasoline, aviation fuel, crude oil, and LPG to any other organic or aqueous solvent. Vapor pressure testing is used to determine the volatility of petroleum products, which is an essential factor in product development. By measuring the vapor pressure of a product, manufacturers can determine its boiling point, which is a critical factor in determining the product’s performance.

Interpreting Test Results

When it comes to Vapor Pressure Testing, interpreting test results is an essential aspect of the process. The following subsections provide guidance on how to analyze test data, compare results to standards, and understand the implications of test results.

Data Analysis

The first step in interpreting test results is analyzing the data that was collected during the test. This includes the pressure and temperature measurements taken at various stages of the test. You should look for any patterns or anomalies in the data that may indicate issues with the test equipment or the sample being tested.

One useful tool for data analysis is a graph that plots pressure versus temperature. This graph can help identify the vapor pressure of the sample at different temperatures. You can also use the graph to determine the boiling point of the sample, which can be useful for comparing results to standards.

Comparative Standards

Comparing test results to established standards is another crucial step in interpreting test results. There are various standards and regulations that may apply to your particular industry or application. For example, the American Society for Testing and Materials (ASTM) has published a standard method for determining the vapor pressure of petroleum products.

Comparing your test results to established standards can help you determine whether your sample meets regulatory requirements or industry standards. If your results fall outside of the acceptable range, you may need to take corrective action or retest the sample.

Result Implications

Understanding the implications of test results is the final step in interpreting test results. The implications of your results will depend on the specific application and industry. For example, in the oil and gas industry, high vapor pressure can indicate safety hazards, such as the risk of explosion or fire.

In other industries, such as the fragrance or flavor industry, vapor pressure can be an important factor in the quality and consistency of the final product. Understanding the implications of your test results can help you make informed decisions about how to proceed with your project or application.

In conclusion, interpreting test results is a critical aspect of Vapor Pressure Testing. Analyzing data, comparing results to standards, and understanding the implications of your results can help you make informed decisions and ensure the safety and quality of your products or processes.