Zeal Instruments participated in the Fifth China International Chemical Process Safety Symposium

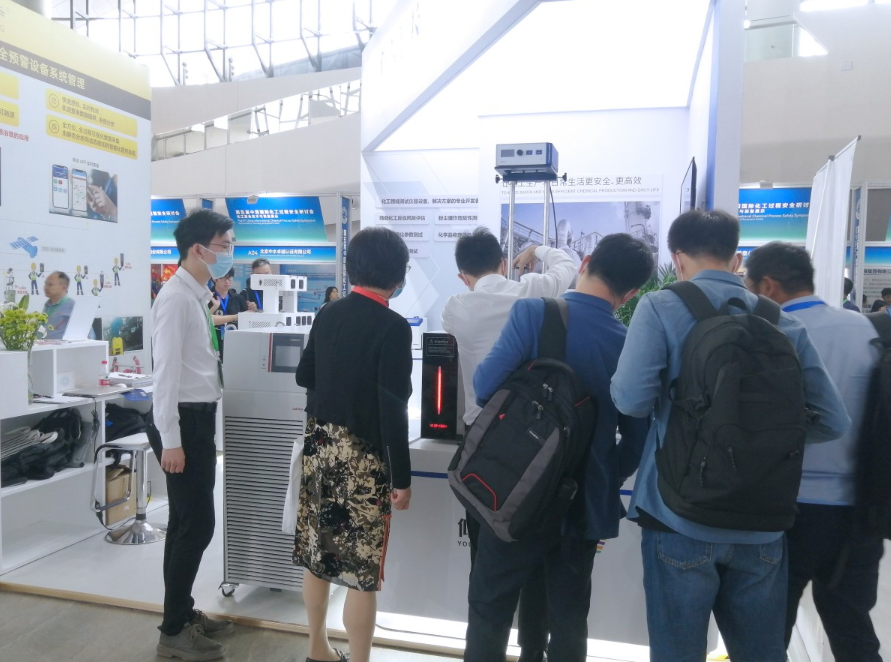

On May 25th to 26th, 2023, Zeal Instruments showcased their cutting-edge Reaction Safety Risk Assessment Testing Solutions at the Fifth China International Chemical Process Safety Symposium in Yantai, Shandong.

This symposium, renowned as the largest-scale event in China’s chemical safety domain, attracted over a thousand domestic and international participants, including experts, scholars, and representatives from chemical enterprises. The event featured insightful discussions on risk assessment and management, digitization and smart technologies in safety, and leadership and accountability in safety protocols.

Leadership and Innovation in Chemical Safety

Zeal Instruments emerged as a pivotal contributor to the symposium, showcasing a range of innovative instruments aimed at enhancing chemical safety. Among the showcased solutions were the Adiabatic Calorimeter, Rapid Screening Calorimeter, Automated Reaction Calorimeter, Microscale Closed-Cup Flash Point Tester, and Micro Vapor Pressure Determination Instrument.

These state-of-the-art devices garnered unanimous acclaim from attendees for their precision, efficiency, and reliability in assessing reaction safety risks. With years of technical expertise and industry experience, Zeal Instruments has become a trusted partner for Contract Research Organizations (CROs), Contract Manufacturing Organizations (CMOs), refineries, and third-party testing agencies, providing comprehensive testing solutions tailored to the chemical industry’s evolving needs.

Empowering Safety through Technology

Zeal Instruments’ commitment to advancing safety through technology is exemplified in its array of instruments designed to mitigate risks associated with chemical reactions. The Adiabatic Calorimeter, for instance, enables precise measurement of heat released or absorbed during chemical processes, facilitating early detection of potential hazards such as runaway reactions. These instruments collectively empower chemical industry stakeholders to proactively identify and address safety risks, ensuring the integrity of operations and the well-being of personnel.

Navigating Reaction Safety: A Case Study Approach

1. Lithium Battery Manufacturing: Thermal Safety and Management Design

Lithium battery manufacturing involves intricate processes that require careful attention to thermal management and safety. With the proliferation of electric vehicles and portable electronic devices, the demand for lithium batteries has surged, emphasizing the importance of ensuring their safe production. Zeal Instruments collaborates with lithium battery manufacturers to develop comprehensive thermal safety and management designs. By conducting thorough risk assessments and implementing advanced monitoring systems, Zeal Instruments helps mitigate the risk of thermal runaway reactions, ensuring the safety and reliability of lithium battery products.

2. Advanced Materials Development: Thermal Properties and Non-Destructive Testing

In the realm of advanced materials development, understanding thermal properties is crucial for ensuring product stability and performance. Whether it’s polymers, composites, or ceramics, Zeal Instruments offers non-destructive testing solutions to characterize thermal properties accurately. By leveraging advanced instrumentation and analytical techniques, Zeal Instruments enables researchers and engineers to assess thermal conductivity, diffusivity, and other critical parameters essential for optimizing material design and performance.

3. Petrochemical Refining: Rapid Characterization of Physicochemical Parameters

Petrochemical refineries operate in complex environments where rapid and accurate characterization of physicochemical parameters is essential for ensuring process safety and efficiency. Zeal Instruments provides rapid testing solutions tailored to the needs of petrochemical refining operations. From measuring flash points to analyzing vapor pressures, Zeal Instruments’ instrumentation enables refineries to quickly assess key parameters, identify potential hazards, and implement appropriate risk mitigation measures, thereby enhancing operational safety and reliability.

4. Fine Chemical Production: Risk Assessment of Fine Chemical Reactions

Fine chemical production involves synthesizing high-value compounds with precision and efficiency. However, the intricate nature of fine chemical reactions poses inherent safety risks. Zeal Instruments conducts comprehensive risk assessments of fine chemical reactions, identifying potential hazards such as exothermic reactions or reactive intermediates. By employing advanced calorimetry and analytical techniques, Zeal Instruments assists fine chemical manufacturers in optimizing reaction conditions, minimizing risks, and ensuring product quality and safety.

5. Energetic Materials Synthesis: Safety Assessment of Energetic Materials

Energetic materials, including explosives and propellants, require rigorous safety assessments throughout the synthesis process. Zeal Instruments specializes in conducting safety assessments of energetic materials, leveraging advanced instrumentation to analyze reaction kinetics, heat release rates, and other critical parameters. By providing insights into the thermal behavior and stability of energetic materials, Zeal Instruments enables manufacturers to mitigate risks, adhere to regulatory requirements, and uphold the highest standards of safety and quality.

Conclusion

In conclusion, Zeal Instruments’ participation in the Fifth China International Chemical Process Safety Symposium underscores its leadership and innovation in enhancing chemical safety. Through its state-of-the-art testing solutions, the company continues to empower industry stakeholders with the tools and insights needed to mitigate risks, uphold compliance, and drive operational excellence. As the chemical industry evolves, Zeal Instruments remains steadfast in its commitment to advancing safety, reliability, and sustainability across the sector.